Steel-framed balconies have become a hallmark of contemporary architecture. They offer occupants a space to relax, socialize, and connect with the outdoors. However, this common architectural design can come at a cost, thermal bridging. In this post, we will discuss the challenges posed by thermal bridging in steel balconies, helping you understand why it’s an issue worth addressing.

Table of Contents

- Understanding Thermal Bridging

- Causes of Thermal Bridging in Steel Balconies

- How Structural Thermal Breaks Work

- Benefits of Structural Thermal Breaks

- Design Considerations for Structural Thermal Breaks

- Balancing Form with Function

Understanding Thermal Bridging

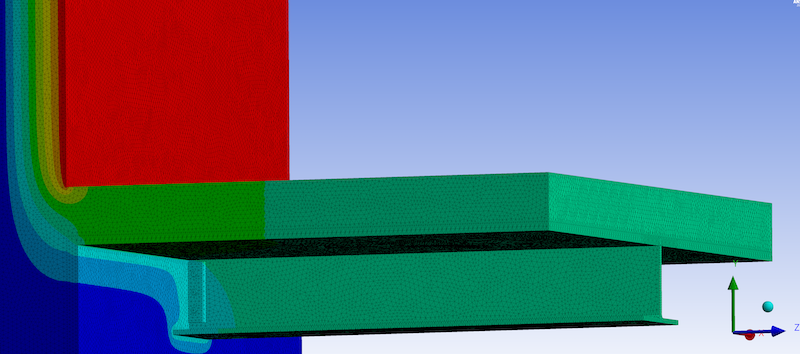

Thermal bridging is where heat travels through a building component at a faster rate than its surrounding insulation. In the context of steel-framed balconies, thermal bridging typically occurs through the continuous steel beam that penetrates the building envelope. This creates a path of least resistance for heat to flow through, that can lead to several problems:

Energy Inefficiency: One of the primary consequences of thermal bridging in steel balconies is the increase in energy consumption. Heat loss through the steel frame that penetrates the insulation line decreases the building envelope performance, and requires more energy to maintain a comfortable indoor temperature.

Cold Spots: Thermal bridging results in uneven temperatures in the living space adjacent to the balcony. This can make the indoor environment uncomfortable and disrupt the efficient use of the space.

Condensation Issues: The temperature difference created by thermal bridging causes warm, moist air to cool rapidly when it comes into contact with the cold surface. The liquid water created by condensation can collect on the cold surfaces, potentially leading to moisture-related issues like mold growth, structural damage, and aesthetic problems in the building.

Causes of Thermal Bridging in Steel Balconies

Thermal bridging in steel-framed balconies can be attributed to several factors:

High Thermal Conductivity: The material steel has a high thermal conductivity that readily conducts heat.

Design Choices: The design and layout of steel balconies can also contribute to thermal bridging. For example, a continuous steel structure that extends from the inside to the outside of a building can serve as a direct pathway for heat loss through the building envelope.

Lack of Structural Thermal Breaks: In many inefficient steel balcony designs, structural thermal breaks are ignored. A structural thermal break is an insulating component placed between conductive materials to interrupt the flow of heat, resulting in a more energy efficient connection.

How Structural Thermal Breaks Work

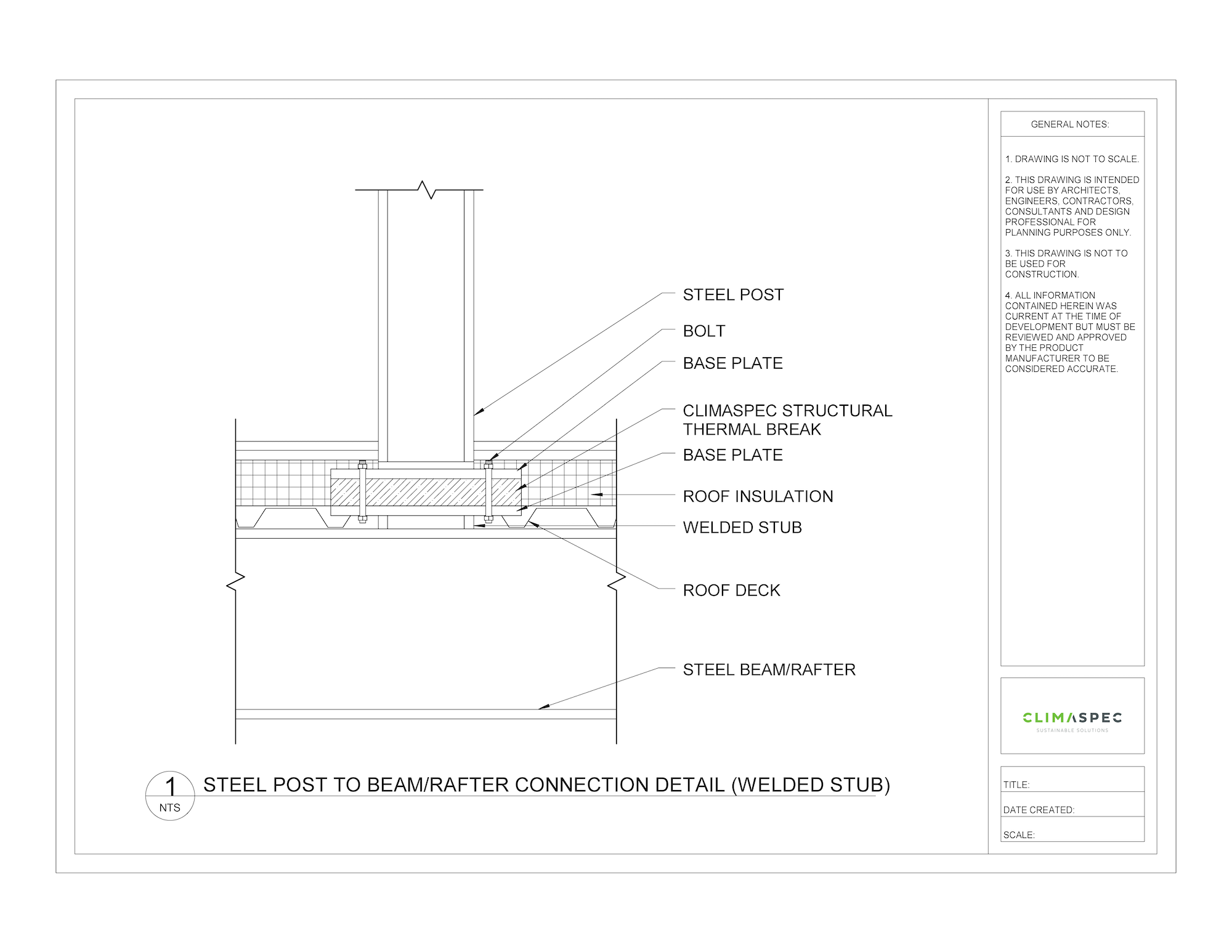

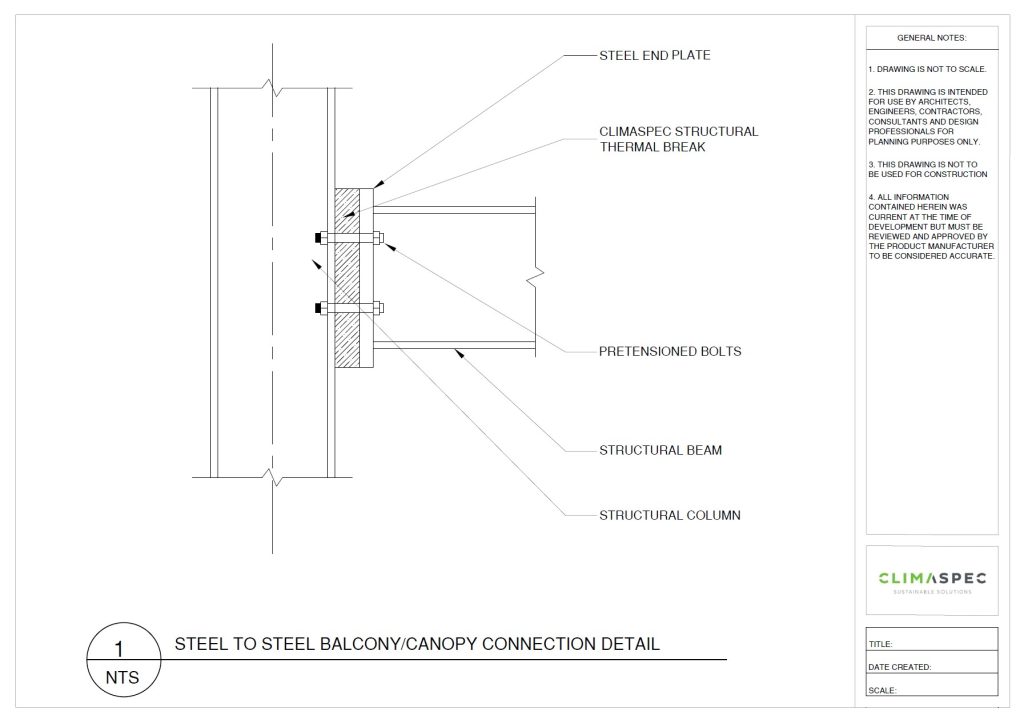

So, what’s the solution to the thermal bridging challenge in steel balconies? The solution is installing structural thermal breaks. These innovative insulating components have low thermal conductivity properties and are installed strategically within the steel connection at points where thermal bridging would typically occur.

Structural thermal breaks are designed to disrupt the flow of heat through the steel structure by creating a thermal barrier that prevents heat from escaping, significantly improving the energy efficiency of steel-framed balconies. It is important to select a structural thermal break with strong mechanical properties so that the structural integrity of the connection is maintained.

Benefits of Using Structural Thermal Breaks

The numerous advantages of incorporating structural thermal breaks in steel balcony designs are significant:

Enhanced Energy Efficiency: Structural thermal breaks are the key to improving energy efficiency. By eliminating thermal bridging, they reduce the heating and cooling requirements, resulting in energy savings and lower utility bills.

Improved Comfort: Structural thermal breaks help create a more comfortable indoor environment by reducing cold spots.

Condensation Prevention: The absence of thermal bridges also reduces condensation risks. This, in turn, mitigates potential moisture-related issues such as mold growth and structural damage.

Sustainability: Reduced energy consumption translates into a smaller environmental footprint. By integrating structural thermal breaks into steel balcony designs, you contribute to sustainable construction practices.

Design Considerations for Structural Thermal Breaks

Structural thermal breaks are powerful solutions for improving energy efficiency and occupant comfort in steel-framed structures. To ensure the successful integration of thermal breaks, several crucial design considerations must be taken into account.

Let’s explore these factors to help you make informed decisions when incorporating structural thermal breaks into your construction projects:

Structural Thermal Break Selection

The choice of your structural thermal break is paramount. The product should have a significantly lower thermal conductivity than steel to effectively interrupt heat transfer through the structure, while also possessing a high compressive strength to maintain structural integrity.

Strategic Placement

The effectiveness of structural thermal breaks is closely tied to their placement within the steel structure. The following factors must be considered when determining where to place thermal breaks:

- Connection Points: Structural thermal breaks are typically placed at connection points between the steel frame and other external building components. These are the areas most prone to thermal bridging and require particular attention. Examples are beam to column and beam to beam connections.

- Continuous Barrier: Ensure that the thermal breaks create a continuous thermal barrier and is installed within the building envelope. The goal is to create a continuous line of insulation with the structural thermal break and adjacent insulation. Also, minimize any gaps or interruptions that could compromise the buildings envelope effectiveness.

Engineering Expertise

Collaboration with experienced structural engineers and design professionals is vital for the successful implementation of structural thermal breaks. Structural engineers should perform precise calculations to ensure the steel structure’s load-bearing capacity and compliance with local building codes. This analysis ensures the safe integration design of thermal breaks. If required, ClimaSpec is able to provide structural calculations for the bolt through structural thermal break design.

Balancing Form with Function

Steel-framed balconies undoubtedly add value to a building and occupants, but ignoring the thermal bridging concerns can lead to decreased occupant discomfort levels and increased energy costs. Structural thermal breaks offer an effective solution to this challenge, ensuring that your steel balcony combines purpose with energy efficiency.

As the construction industry continues to prioritize energy-efficient and sustainable design, structural thermal breaks are poised to become an essential feature in the creation of modern, high-performance steel balconies. By addressing thermal bridging with these innovative solutions, you can enjoy the best of both worlds – an aesthetically pleasing balcony that’s also environmentally responsible and energy-efficient.

If you want to download typical details, product specifications, or receive pricing of structural thermal breaks for steel balconies, learn more about ClimaSpec TB.