Energy efficiency and sustainability have become key priority goals for construction and building design. To achieve these goals, architects and engineers continually seek innovative solutions to minimize heat transfer and reduce energy consumption. One such solution is the incorporation of structural thermal breaks in column connection designs. In this post, we will explore how steel column thermal breaks are vital for improving the energy efficiency of columns that penetrate the insulation line of a building.

Table of Contents

- Understanding Thermal Breaks in Structural Columns

- Types of Buildings that Benefit from Column Thermal Breaks

- Benefits of Column Thermal Breaks

- Including Thermal Breaks in Column Base Designs

- Summary

Understanding Thermal Breaks in Structural Columns

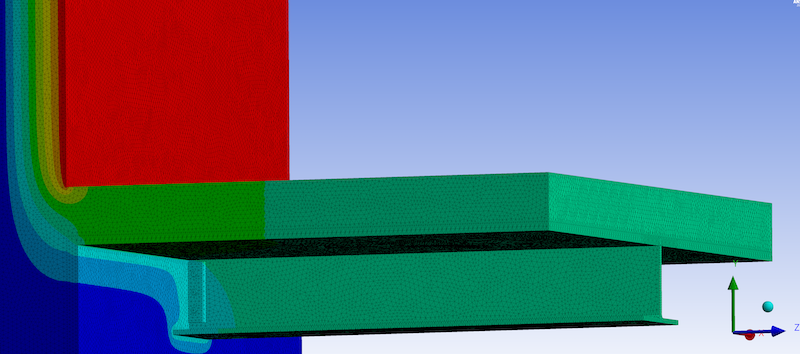

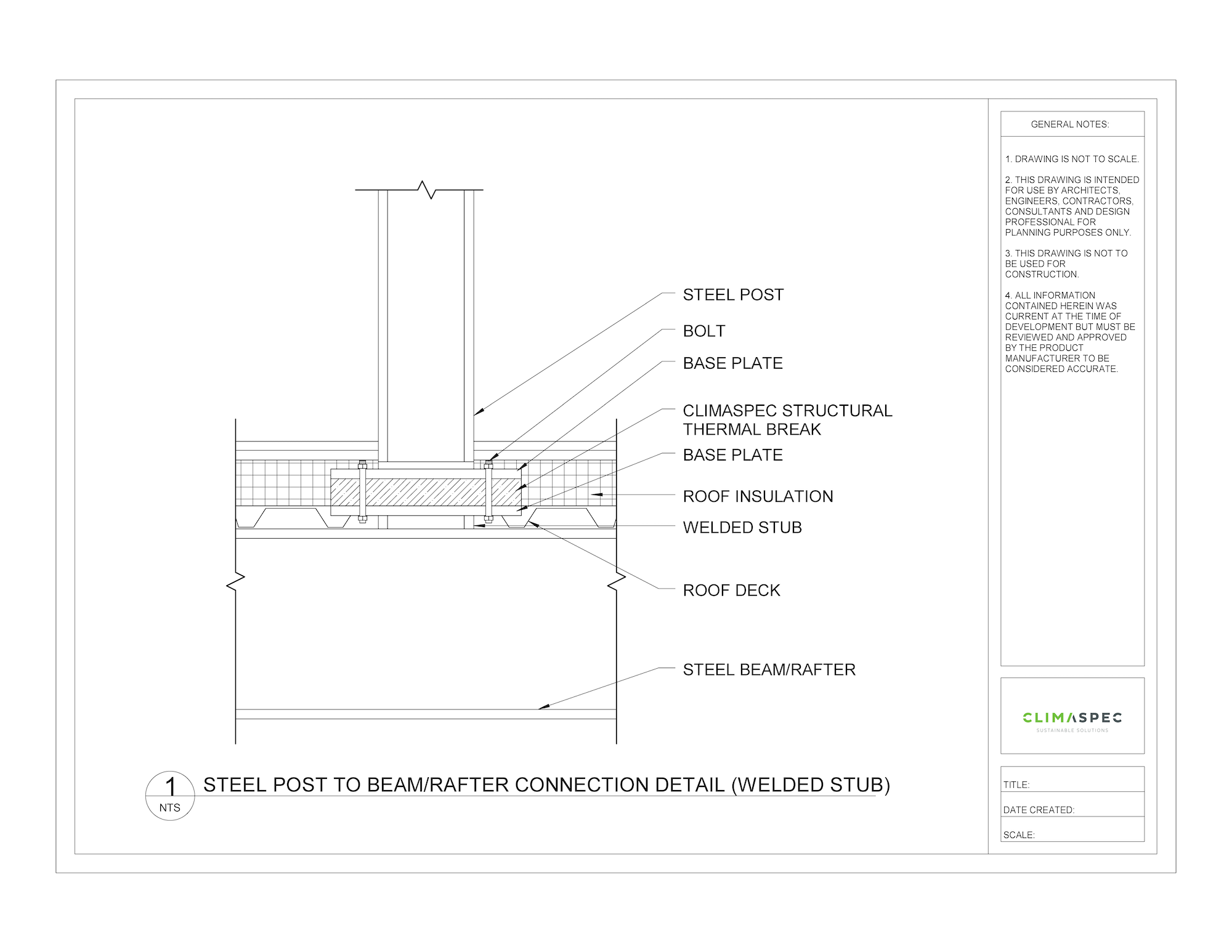

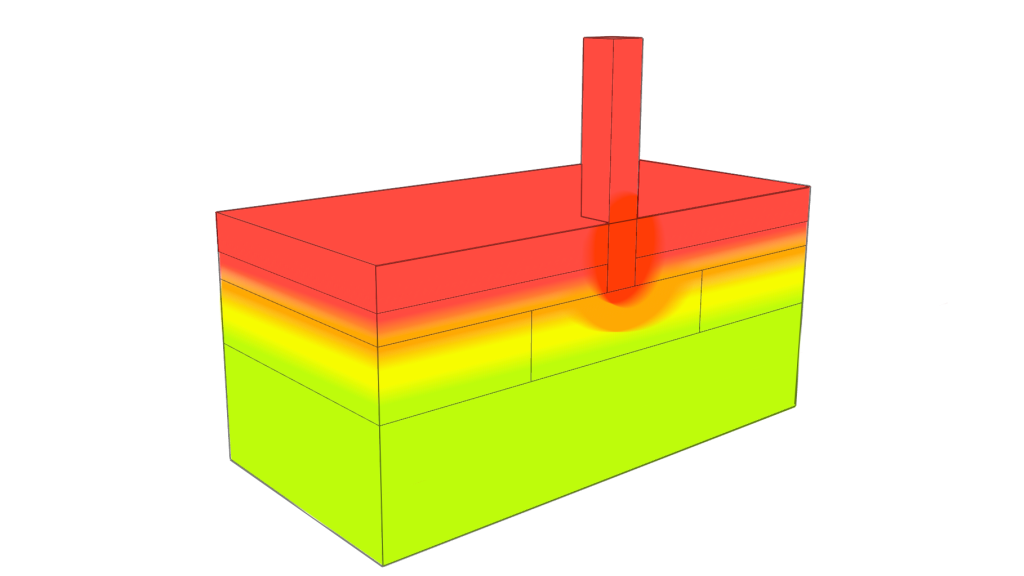

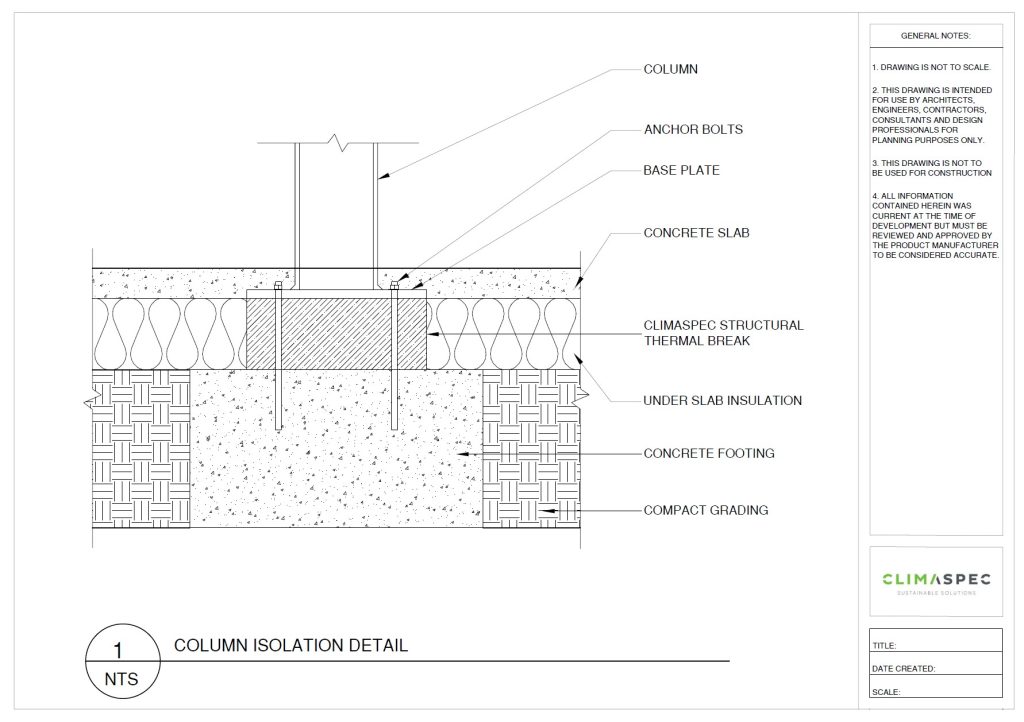

Thermal breaks, in the context of column bases, refers to the interruption of heat flow through the column base plate and the concrete footing/slab or embedded plate. Without a thermal break, this type of connection penetrates the below slab insulation line and causes a thermal bridge. Installing a thermal break under the column base plate creates a continuous insulation line with the surrounding below slab insulation, this achieves a reduction in unwanted heat loss that helps maintain a more stable and energy-efficient indoor environment.

Types of Buildings that Benefit from Column Thermal Breaks

Structural thermal breaks should be used under any column base that penetrates the insulation line and causes a thermal bridge. It is important to reference the building design requirements along with code compliance to understand the required thickness for the thermal break. Highly temperature regulated structures such as cold storage facilities and data centers can require thicker thermal breaks to ensure the design requirements are met.

Benefits of Column Thermal Breaks

The benefits of including thermal breaks in column base design are varied but substantial:

Reduced Heat Loss

One of the primary functions of thermal breaks in column bases is to minimize heat loss. Traditional construction materials such as concrete and steel are excellent conductors of heat. When these materials bridge the connection between a building’s structure and its foundation, they create a pathway for heat to escape. By installing thermal breaks, you can effectively reduce heat transfer, energy consumption, and the associated costs.

Increased R-Value

Thermal breaks increase the effective R-Value of a building by isolating the highly conductive materials used in the column base design.

Lower HVAC Requirements

Increased building energy efficiency, decreases the load requirements for the building’s HVAC system, resulting in energy savings and lower utility bills for the building owner.

Improved Comfort

The use of thermal breaks in column bases contributes to increased comfort for building occupants. By preventing cold spots and temperature variations around the columns, thermal breaks help maintain a more consistent and comfortable indoor environment. This is essential for the well-being of residents and employees in residential and commercial structures alike.

Condensation Prevention

Thermal breaks also play a role in condensation prevention. When warm humid air encounters cold surfaces, condensation can form, potentially leading to mold and structural damage. Thermal breaks act as a thermal barrier that reduces temperature differentials, reducing the risk of condensation and its associated problems.

Long-Term Savings

While integrating thermal breaks into column base design may involve initial costs, the long-term benefits outweigh the investment. Lower energy consumption, reduced maintenance costs, and a prolonged lifespan of the structure all contribute to substantial savings over time.

Including Thermal Breaks in Column Base Designs

When considering the inclusion of thermal breaks in column base design, it is essential to follow best practices to ensure their effectiveness:

- Ensure the thickness of the thermal breaks meets the design requirements. Remember, the thicker the thermal break, the better the thermal performance.

- Collaborate with ClimaSpec to select the appropriate thermal break product and ensure the design load-bearing requirements are met.

- Ensure that thermal breaks are installed correctly and without gaps to prevent leakage.

- Install the thermal break with anchor bolts to secure the connection.

Bonus Step

- Integrate other thermal breaks into the building’s overall design and construction plans to maximize the building envelope performance.

Summary

The inclusion of steel column thermal breaks in column base designs is a crucial step toward improving the energy efficiency, occupant comfort levels, and sustainability of buildings. By minimizing heat transfer and preventing condensation issues, thermal breaks contribute to a more energy-efficient and structurally efficient design. This, in turn, benefits the triple bottom line of economic, environmental, and social well-being of the building occupants and building owners. As construction practices evolve, the use of thermal breaks in column bases remains a fundamental aspect of sustainable building design.

If you want to download typical details, product specifications, or receive pricing of structural thermal breaks for column base designs, learn more about ClimaSpec CI column base thermal break.