When it comes to optimizing the energy efficiency of buildings, one crucial element that often gets overlooked is thermal breaks. These building insulation components play a pivotal role in reducing heat transfer through a building envelope, and maintaining a comfortable indoor environment while saving on energy costs. The purpose of this guide is to provide clarity on what thermal breaks are, how they work, the benefits, and some frequently asked questions. For further information contact one of our thermal bridging specialists so we can assist with any questions you have.

Table of Contents

- What is a thermal break?

- How do thermal breaks work?

- Why are thermal breaks important?

- Benefits of thermal breaks?

- Frequently asked questions about thermal breaks

- The future of thermal breaks

- Summary

What is a Thermal Break?

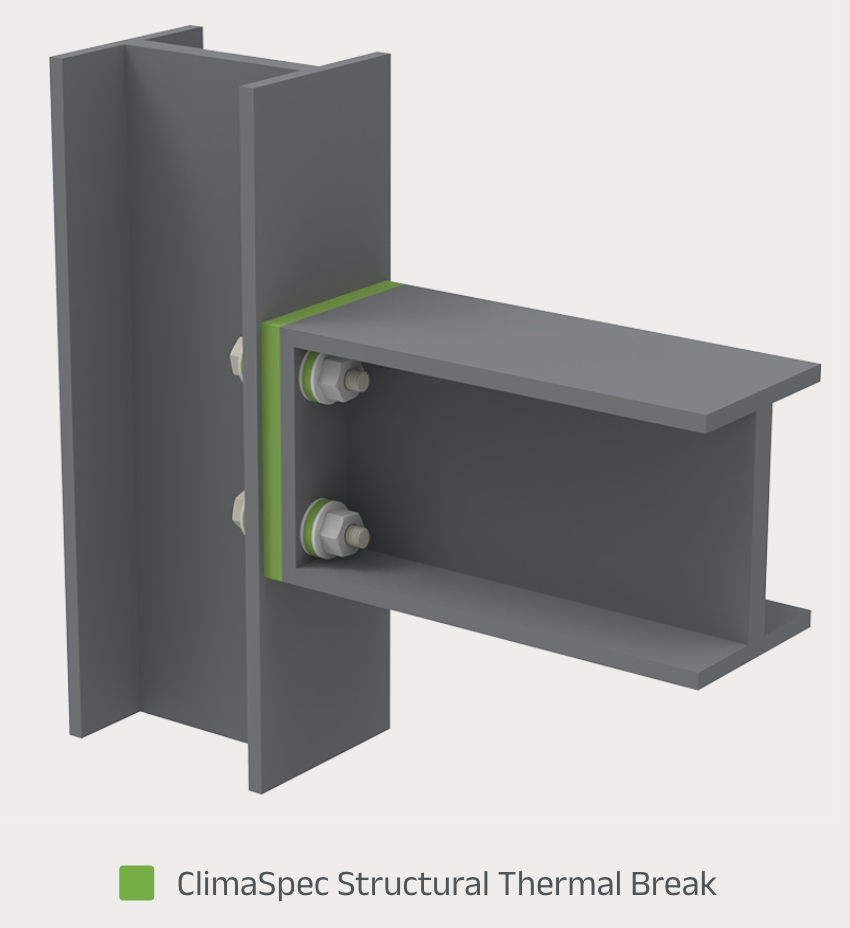

A thermal break, also known as a structural thermal break in construction, is an insulating material that is strategically placed between highly conductive structural components within the building envelope, acting as a thermal barrier to interrupt the flow of thermal energy. Materials such as aluminum, steel, and concrete are examples of conductive structural components that can be efficiently thermally broken. By reducing the transfer of heat from one side of the structural component to the other, the thermal break acting as a thermal barrier can significantly enhance the energy efficiency of a wall, floor, or roof design.

How do Thermal Breaks Work?

A thermal break possesses a low thermal conductivity when compared to structural materials such as aluminum, steel, and concrete. The lower the thermal conductivity, the lower the rate heat can pass through the material. When heat or cold attempts to transfer through the structure, the thermal break resists this flow, creating a barrier that minimizes temperature transfer. This ensures that the building interior remains at a more consistent, comfortable temperature. Also, reducing the rate heat can pass through a structural element, increases the thermal resistance of a connection or assembly. In construction terms it would mean the R-Value (thermal resistance) increases, the higher the R-Value, the higher the energy efficiency.

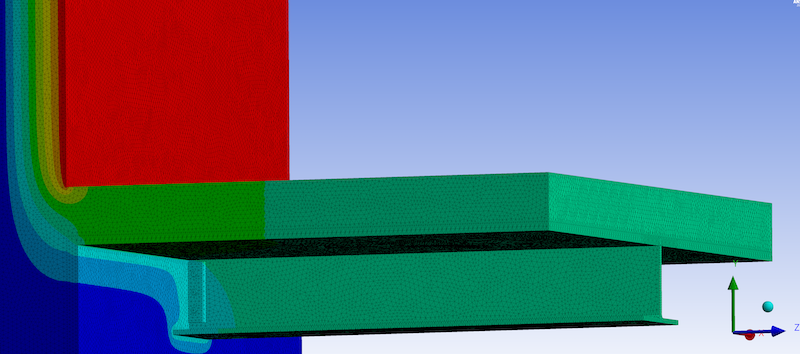

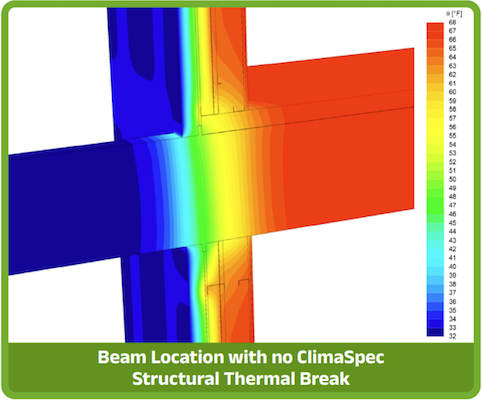

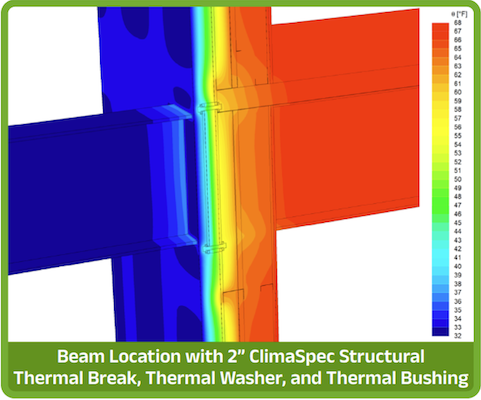

Note: The thermal modeling images below are compare a steel beam connection that is penetrating a wall. In this scenario the interior is warm and the exterior is cold, although remember thermal bridging can happen in both cold and hot climates. The temperature difference between the exterior and interior is one of the most important factors for the performance of a thermal break and the significance of a thermal bridge.

In the thermal model with no ClimaSpec Structural Thermal Break, thermal bridging is occurring due to a highly conductive material (steel) bypassing the continuous wall insulation. The color gradient that spans across the interior, through the building envelope, and to the exterior represents a thermal bridge.

The image below uses a 2″ ClimaSpec Structural Thermal Break with thermal washers and bushings for the bolts. Take note of the colors, the warm interior is red, the cold exterior is blue, and the building envelope no longer has this large color gradient. Using insulation strategies such as thermal breaks has reduced the unwanted heat transfer (thermal bridging) through the building envelope.

Additionally, thermal breaks are a type of load-bearing insulation, the reason they are is due to thermal breaks being installed and connected between structural elements such as beams, column bases, foundation walls, parapets, shelf angles, and more. Thermal breaks are specifically designed to be used in a variety of structural connections, ensuring the structural integrity of the connection is maintained. Depending on the thermal break type and the building components they are thermally breaking, different connections are used. For example, steel-to-steel is a bolt connection, concrete-to-concrete is with rebar, concrete to steel can be bolts, threaded rods, and embedded plates.

Fire characteristics are also critical, thermal breaks are installed within the building envelope, and when fully installed they are not exposed to the elements. Rather, they are surrounded by other building materials such as continuous insulation that can be both non-combustible and combustible as well as non-combustible structural elements such as steel, aluminum, concrete, and masonry. Due to the location of thermal breaks within the building envelope, both the thermal break and adjacent building component fire characteristics should be considered.

Note: If you are unsure about selecting the correct thermal break, it is important to confirm with the thermal break manufacturer that the suitable product has been specified for the connection. At ClimaSpec, our design assistance services, such as project detail review, thermal modeling, and structural calculations, ensure qualified industry professionals, including Architects, Structural Engineers, and consultants, are sufficiently supported throughout the specification process.

Why are Thermal Breaks Important?

Buildings account for nearly 40% of all greenhouse gas emissions (GHGs), according to Architecture 2030. By effectively reducing the building’s carbon footprint, it helps achieve the global target of net zero.

Note: Net zero, refers to reducing greenhouse gas emissions to almost zero, with any leftover emissions being reabsorbed from the atmosphere by things such as forests and oceans. However, commitments across the participating countries thus far are far from sufficient. Emissions must be cut by 45% by 2030 to meet the Paris Agreement’s goal of keeping global warming to 1.5°C. This means in order to achieve the 2050 net zero goals we must first concentrate on the immediate future of 2030.

Institutions such as the AIA have created an actionable climate strategy with standards and goals called “The AIA 2030 Commitment”. The aim is to have net zero emissions in the built environment. AIA additionally say “To make the biggest impact, we must all commit to net zero emissions by 2030—a path that requires strong, immediate action.”

Canada’s 2030 Emissions Reduction is to reduce national greenhouse gas emissions by 40% relative to 2005 levels by 2030. Additionally, The Government of Canada will invest $150 million to develop a national net zero by 2050 buildings strategy, the Canada Green Buildings Strategy. Key areas of focus are to launch a new net zero building code acceleration fund, develop a low carbon building materials innovation hub, improve federal capacity and technical support, develop and adopt net zero emission codes, and revise existing building codes.

So how do thermal breaks contribute to net zero and climate initiatives such as the AIA 2030 and Canada Green Buildings Strategy Commitment? The main purpose of thermal breaks is to increase the thermal performance of construction connections that penetrate the building envelope, in doing so improving the energy efficiency of the building. If the building is more energy efficient it means less energy is required to maintain the desired interior temperature. Why? Because the thermal break reduces unwanted heat loss. If less energy is required to maintain the desired interior temperature, it means the building energy consumption will be lower, and so will the carbon footprint of the building.

Not to mention, by lowering building energy consumption the operating cost of a building can decrease due to lower energy bills. Innovate insulation methods such as thermal breaks can not only help to reduce the carbon footprint of a building, but also provide long-term energy savings.

Benefits of Thermal Breaks

There are various benefits of incorporating thermal breaks into your construction projects:

Energy Efficiency: As previously mentioned, one of the primary advantages of thermal breaks is the contribution to energy efficiency. By reducing heat transfer, they help maintain a stable indoor temperature, reducing the need for heating and cooling.

Lower Operational Costs: Buildings can benefit from lower energy bills due to increasing the building envelope energy efficiency, which in turn reduces heating and cooling energy consumption.

Improved Comfort: Thermal breaks create a more comfortable indoor environment by minimizing temperature extremes that can cause cold spots. They help keep interiors warm in the winter and cool in the summer, ensuring that occupants enjoy a consistent and pleasant atmosphere year-round.

Improved Performance: By minimizing unwanted heat loss with thermal breaks, more consistent temperatures are achieved within temperature regulated facilities such as cold storage and data centers. Additionally, heating and cooling requirements can be reduced due to the increased energy efficiency of the building or room.

Condensation Control: Another benefit of thermal breaks is their ability to control condensation. By minimizing temperature differentials between indoor and outdoor surfaces, they reduce the risk of moisture buildup, which can lead to mold and structural damage.

Increased Lifespan: Thermal breaks can also contribute to increasing the lifespan of a building due to the improved design of the building envelope.

Longevity: High-quality thermal break products are designed to be durable and have long lifespans. Withstanding rigorous environments that provide reliable insulation methods that can last the lifetime of the connection.

Code Compliance: Thermal breaks can be used in a building design to ensure energy compliance for a variety of energy codes such as IECC, ASHRAE 90.1, and NECB.

LEED: Incorporating thermal breaks in a building design aids contribution towards LEED® Green Building certification credits. Potential points and prerequisites examples are optimized energy performance, minimum energy performance, thermal comfort design, and innovation in design.

Tax Incentives: Using thermal breaks in a building can offer national and local tax incentives. One example is the 179D provision, where a building owner, architect, or engineer who makes qualifying energy efficiency improvements to a commercial property can be eligible for significant tax deductions.

These deductions, increased from up to $1.88 per square foot in 2022 to up to $5.00 per square foot in 2023, rewarding those who embrace energy-efficient practices in the building envelope.

Frequently Asked Questions About Thermal Breaks

Now, let’s look at some common questions people have about thermal breaks:

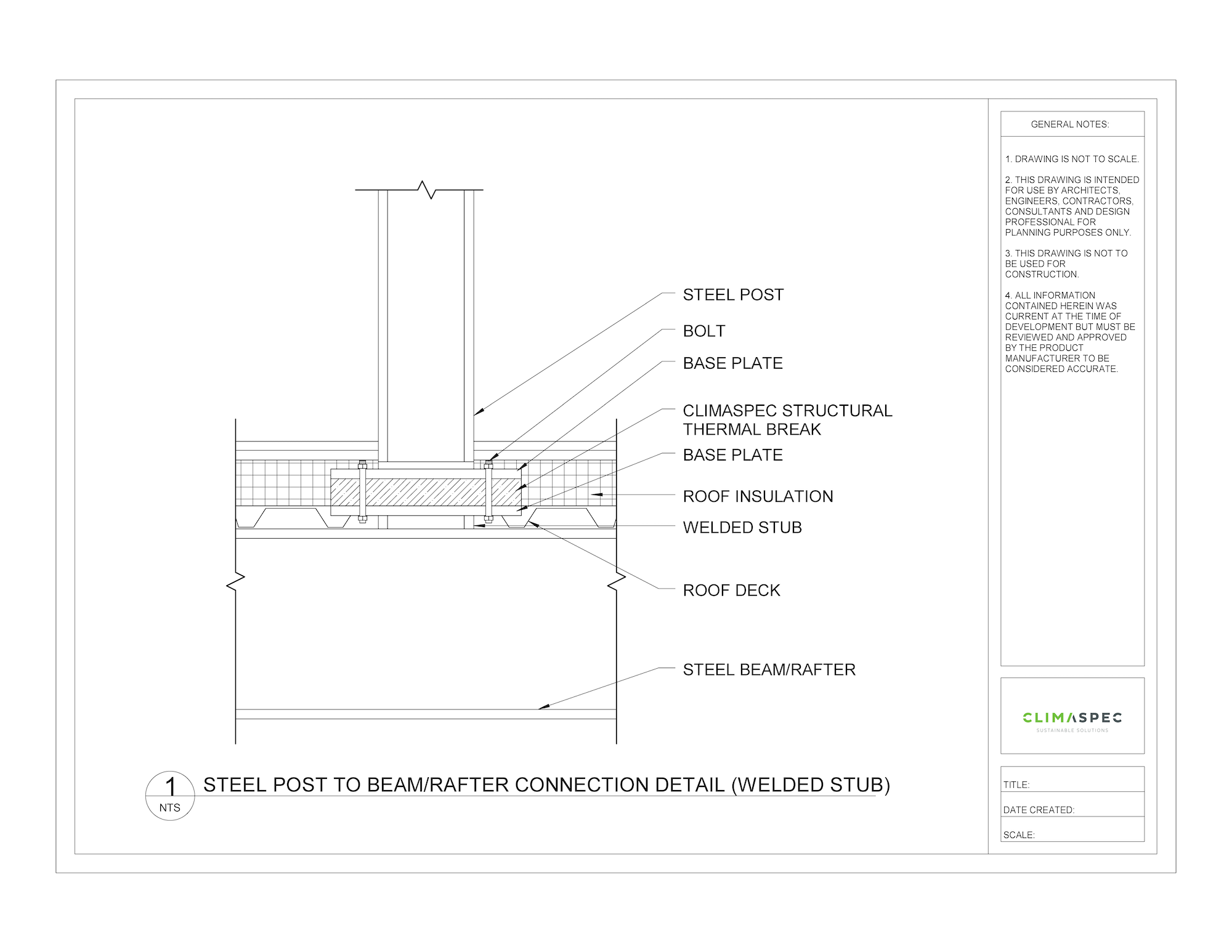

What are common connections where thermal breaks are used?

Thermal breaks can be used in numerous connections within the building envelope.

Foundation examples: column base isolation and foundation to wall transitions.

Wall examples: balconies, canopies, shelf angles, and façade attachments.

Roof examples: wall to roof transitions and roof penetrations such as posts, anchors, HVAC systems.

Are thermal breaks only relevant for cold climates, or do they also benefit buildings in warm regions?

Thermal breaks are beneficial in both cold and warm climates. In hot regions, they help keep interiors cooler by preventing heat transfer, and reducing the need for air conditioning. While in cold climates they minimize heat escaping from the warm interior, reducing the need for heating.

Temperature regulated buildings such as cold storage and data centers also require consistent temperature control all year round, no matter the climate.

Can thermal breaks be used in residential construction, or are they primarily for commercial buildings?

Thermal breaks are suitable for both residential and commercial construction. They offer energy-saving benefits and improved comfort for the residents, making them a valuable addition to residential projects for developers.

Can a thermal break be retrofitted into existing structures?

Yes, they can often be retrofitted into existing buildings, especially in cases where energy efficiency improvements are required. However, the feasibility of retrofitting depends on the specific structure and the intended application.

Are there any building energy codes or standards related to thermal breaks?

Building energy codes and standards vary by location, depending on the State, Province or municipality. Guidelines and standards related to energy efficiency in construction are ASHRAE 90.1-2022, the predicted 2024 IECC, and NECB. These energy standards address mitigated thermal bridges. This can be achieved by using thermal breaks, designers can achieve the mitigated thermal bridging requirements and ensure details are code compliant.

Do thermal breaks have any impact on building resale value?

Energy-efficient features, including thermal break building products, can enhance the resale value of a building. Buyers often appreciate lower energy bills and a more comfortable living or working environment, making buildings with increased energy efficiency more attractive.

What is the payback period for thermal break investments?

The payback period for thermal break investments varies based on factors such as energy costs, climate, and building size. However, many projects see a payback within the earlier stage of the building’s lifespan due to reduced energy consumption.

Are there any limitations to the size or weight of structures that can benefit from thermal breaks?

While thermal breaks are versatile. Larger and heavier structures may require additional design considerations such as oversizing the thermal break to increase the structural capabilities. Consulting with a thermal break manufacturer and an engineer is essential for such cases.

Can a thermal break be used in conjunction with other insulation methods, such as spray foam or fiberglass insulation?

Yes, they can be used alongside other insulation methods to enhance energy efficiency further. Combining insulation methods can provide superior thermal performance of the building envelope.

How can I choose the right thermal break solution for my project?

Choosing the right thermal break solution involves considering factors such as the building’s location, intended use, and the materials used in construction. Consulting with a thermal break manufacturer and with a qualified architect or engineer experienced in energy-efficient design is advisable to make an informed decision.

What are the cost implications of incorporating thermal breaks?

The cost of incorporating thermal breaks into a project can vary depending on factors such as the type of thermal break, the size of the project, and product choices. While there may be an initial investment, the long-term energy savings justify the expense. To receive a customized thermal break quotation for your project, click here.

Can thermal breaks be used in extreme climates?

Yes, they can be used effectively in extreme climates. Thermal breaks are particularly beneficial in regions with extreme temperatures, as the larger the temperature differential between the interior and exterior, the greater the risk of thermal bridging. In turn, this increases the requirement for a thermal break.

The Future of Thermal Breaks

As the construction industry continues to evolve, the future of thermal breaks promises exciting contributions, that will further enhance sustainability, energy efficiency, and overall building performance:

Prefabrication and Modular Construction: Prefabrication and modular construction methods are gaining popularity due to their efficiency and reduced construction timelines. In the future, a thermal break may be seamlessly integrated into prefabricated building components, streamlining the construction process, and ensuring consistent quality.

Positive Energy Buildings: With the use of thermal break products and other energy-efficient solutions, we may see the rise of positive energy buildings (PEB). These structures would generate more energy than they consume, thanks in part to highly effective thermal bridging solutions that minimize energy loss.

Regulatory Standards and Incentives: As governments continue to prioritize energy efficiency and sustainability, we can expect more stringent building codes and standards. Additionally, incentives and rebates for using energy-efficient construction materials should increase.

Lifecycle Assessments: A greater emphasis on lifecycle assessments. Manufacturers will analyze the environmental impact of their products throughout their entire lifecycle, from cradle to grave, to ensure they align with sustainability goals.

Education and Training: Increased education to architects, engineers, and construction professionals about the benefits and optimal use of thermal breaks. Training programs and certifications related to energy-efficient construction methods are already becoming increasingly important.

Summary

Thermal breaks are an essential component of modern construction, playing a significant role in enhancing energy efficiency, reducing heating and cooling costs, and improving overall comfort. By understanding their benefits and addressing common questions and concerns, architects, builders, and property owners can make informed decisions to create more sustainable buildings. Whether you’re starting a new construction project or considering retrofitting an existing structure, incorporating thermal breaks is a smart choice for a greener, more energy-efficient future.

Contact ClimaSpec today for a free consultation on how thermal breaks can improve the energy efficiency of your projects.