Table of Contents

- Understanding Condensation Risks

- Impacts of Condensation on the Building Envelope

- The Role of Structural Thermal Breaks

- Increasing Building Energy Performance

Understanding Condensation Risks

Condensation occurs when warm, moisture-laden air comes into contact with a surface at a lower temperature, causing the moisture to transition from vapor to liquid. In buildings, this commonly leads to the formation of water droplets on surfaces, promoting the growth of mold, compromising structural components, and creating an environment that can lead to the deterioration of building materials.

Impacts of Condensation on the Building Envelope

Condensation can be a destructive influence on a building’s envelope—the protective barrier that shields its interior from the external elements. Understanding the consequences of condensation provides designers and contractors with the insight needed to appreciate the critical role that structural thermal breaks play in maintaining the structural integrity and longevity of a building.

Structural Deterioration: Condensation, if ignored, can lead to potential structural decay. The moisture that accumulates on surfaces can infiltrate the building envelope, leading to rot, corrosion, and degradation. Over time, this can compromise the structural integrity of a connection.

Mold and Mildew Growth: Excessive moisture, a byproduct of condensation, creates an ideal breeding ground for mold and mildew. This not only compromises indoor air quality but also poses health risks to building occupants. The presence of mold can result in respiratory issues and allergic reactions, making it imperative to address condensation-related risks for the well-being building occupants.

Aesthetic Damage: Beyond the structural and health implications, condensation can damage the aesthetics of a building. Stains and discoloration are common consequences of prolonged exposure to moisture. Such visible damage not only detracts from the visual appeal of the structure but may also indicate deeper, more severe issues within the building envelope.

Increased Maintenance Costs: Addressing the aftermath of condensation demands ongoing maintenance efforts and financial investment. Regular inspections, repairs, and potential replacements of damaged materials contribute to increased operational costs. This financial burden emphasizes the importance of proactive measures to prevent condensation-related issues in the building envelope. Such as the installing structural thermal breaks at structural connections that penetrate the building envelope.

Energy Inefficiency: Condensation is also a sign of energy inefficiency. When moisture accumulates on surfaces, it can indicate thermal inefficiencies within the building envelope. As a result, the heating, ventilation, and air conditioning (HVAC) systems must work harder to maintain comfortable indoor temperatures, leading to higher energy consumption and associated costs

Insulation Breakdown: Condensation can impact insulation materials, diminishing their effectiveness over time. Moisture infiltration compromises the thermal resistance of insulation, reducing its ability to regulate temperature.

The Role of Structural Thermal Breaks

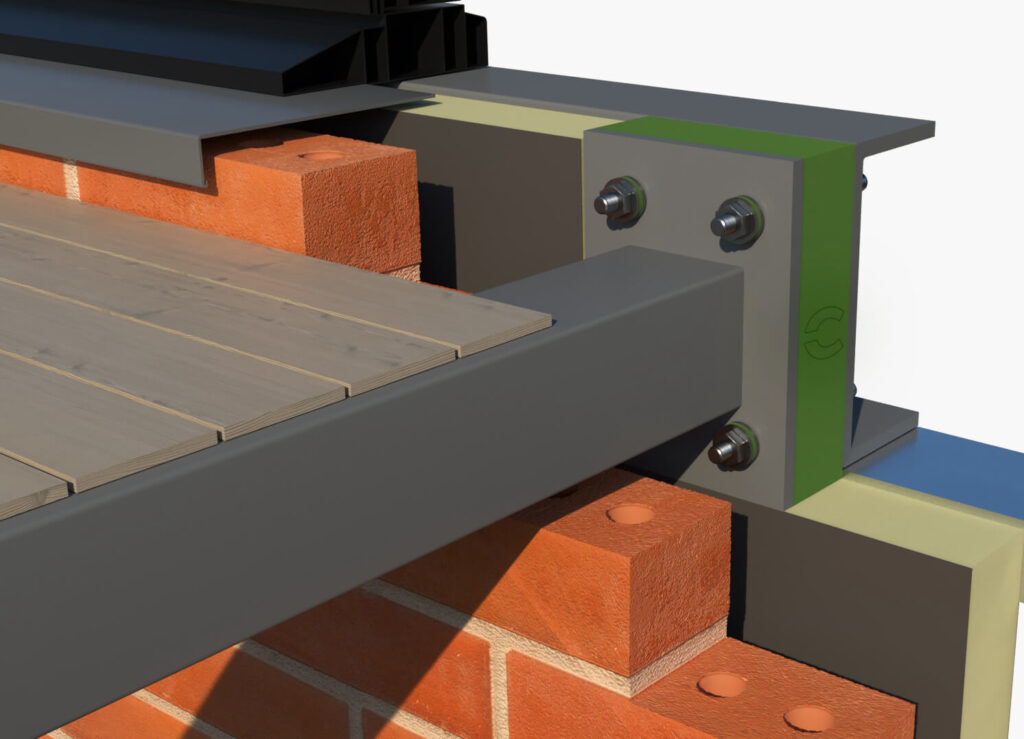

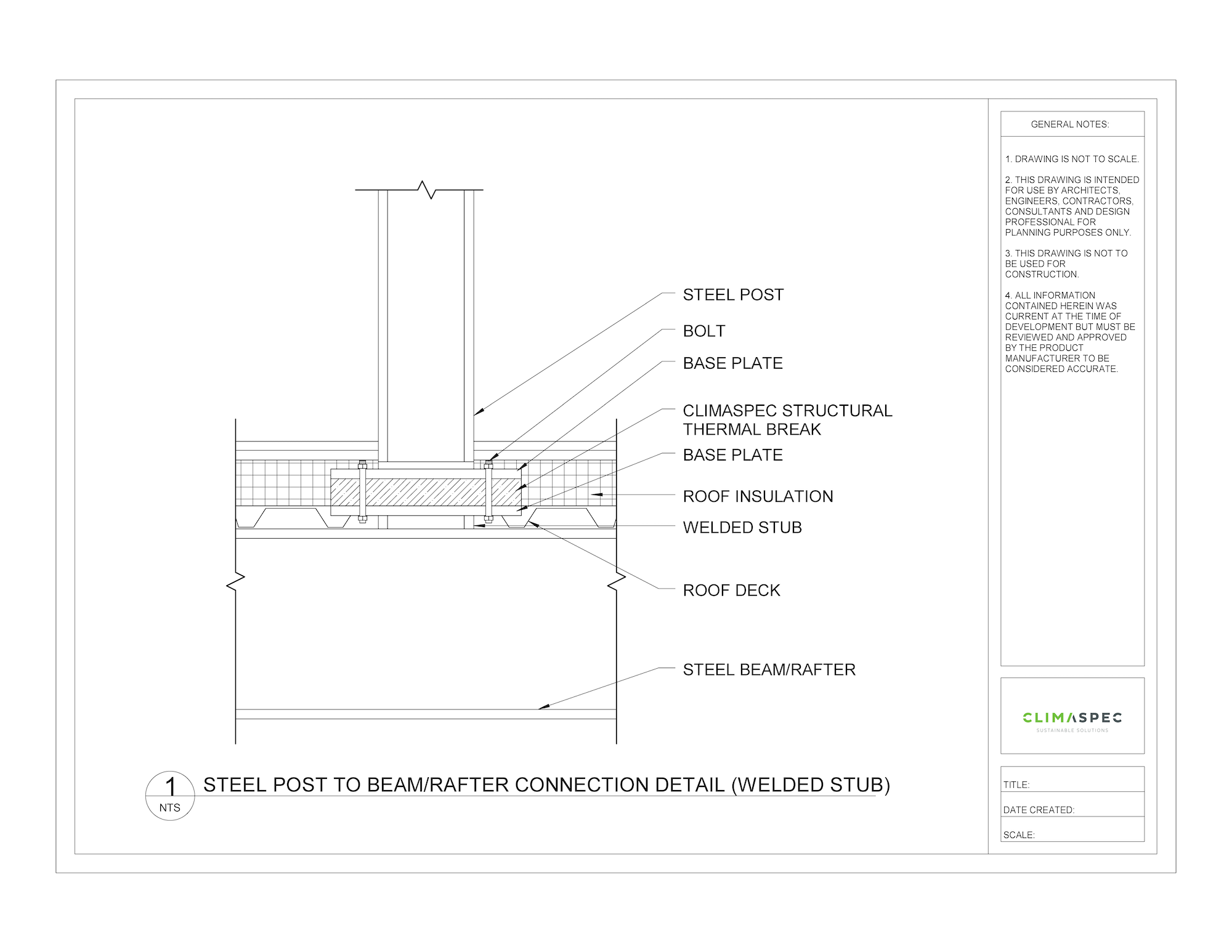

Interrupting Thermal Bridges: Traditional building practices create thermal bridges and pathways for heat to escape through the building envelope due to direct connections of highly conductive structural components such as aluminum, steel and concrete.

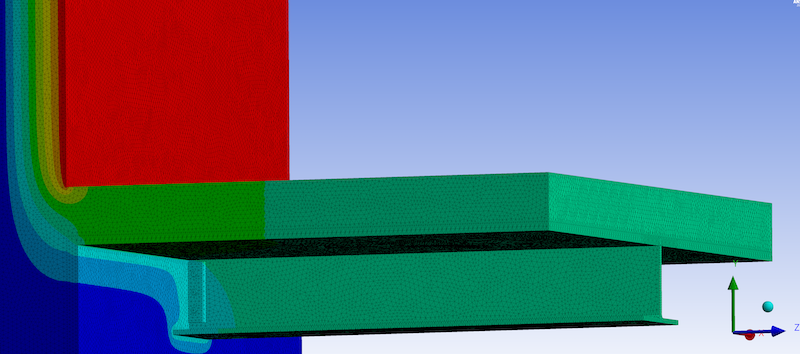

Reducing Condensation Risks: When warm, humid air encounters colder surfaces, condensation becomes a potential occurrence. Structural thermal breaks intervene in this process by strategically interrupting these thermal bridges, preventing the localized heat transfer of surfaces that would otherwise lead to condensation.

Minimizing Cold Spots: Certain areas within a building are more prone to cold spots, making them susceptible to condensation. Structural thermal breaks minimize the occurrence of these cold spots by thermally breaking and insulating structural connections.

Enhancing Insulation Efficiency: Beyond the role in reducing thermal bridging, balcony structural Thermal contributes significantly to overall building envelope insulation efficiency. Improved insulation means that the interior surfaces of a building are better protected against temperature differentials.

Consideration for Climate Variables: Condensation risks vary based on geographical location, climate, and seasonal changes. Structural thermal breaks can be tailored to specific climate variables, providing targeted solutions that align with local weather patterns. This adaptability ensures that buildings are equipped to handle the unique challenges posed by their environment.

Increasing Building Energy Performance

Between temperature, humidity, and building design, Angle Structural Thermal breaks emerge as a key method in mitigating condensation risks. By minimizing thermal bridging and cold spots, enhancing insulation methods, and promoting the overall durability of a structure, thermal breaks offer a proactive solution to condensation challenges faced in building construction.

Contact us today to discuss how ClimaSpec Structural Thermal Breaks can reduce condensation risks within your building envelope designs.